Product Design

Humble beginnings in the world of 3D scanners

First of all, I’m not an engineer. I’m a CG artist. Second of all, being a modeler too, I tried getting my hands on a decent 3D scanner everyday use that is:

1. Affordable, costing under $1000.

2. Gives good results usable in production.

3. Can recreate textures along with scanned mesh.

I wasn’t able to find one. Thing is, good ones are way too expensive. I would have to use it day in, day out to even come close to justifying its price. Cheap ones are mostly laser based, so the resolution is not acceptable. Worst of all, they do not scan the color. There is no acceptable solution that’s under $1000 which gives out good models that will require minimum of post processing work.

So, I decided to build one. As i said, I’m not an engineer, I used to do programming a bit in school before I decided to become a CG artist, so I expected this to be a long and a difficult challenge.

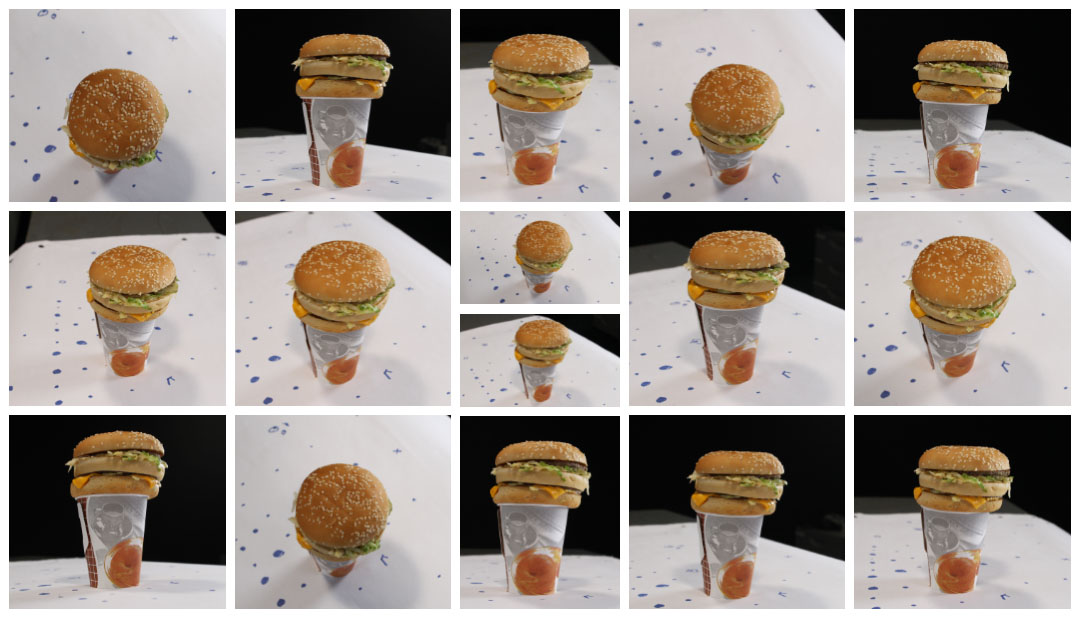

This all started with an assignment I had 3 years ago. We were doing McDonald’s TV ad that, of course, featured a burger and fries. Food had to look delicious, even as a 3D model. I approached the assets modeling by dwelling on 3D scanning an actual burger. Food was ordered, lights were set and the meticulous process of photographing it from all possible angles started. I spent good half a day taking photos, and the second half processing the images and building the dense clouds and fiddling with settings. Results were acceptable but required a lot of manual work to get the production ready assets. This got me thinking, there’s got to be a better way!

(It also made me hungry).

There’s got a be a better way!

This has haunted me ever since. I looked everywhere, but could not find a solution that would suite me. Problem is, I do not need a scanner on a day to day basis, and the price of “professional” solutions is just prohibitively high.

Products on the lower end are some laser based scanners, mostly open source. However, their output quality is just not good enough for a decent production use.

I also don’t want to setup the lights and stage every time I need to make a scan of something, and most definitely I do not want to walk around with a camera and figure out myself if I covered all the angles, and whether there are enough photos to make it work. Furthermore, I want repeatable results, so if something changes I want to be able to scan it again in a month or so, and still get the same results, with same quality, and same lighting.

Therefore, there’s got a be a better way!

I just have to find one.

Since my quest to find an automated scanning solution for under $1000 miserably failed, I figured there is only one way to do it. I’m going to build one my self. That is one bold statement. As I said earlier, I am not an engineer, nor a product designer, but I do have some technical education in electronics, and some programming skills, even though I haven’t used those in a while. Surely I can make 3D models, so, I guess I stand some chance to make something decent and usable. We’ll see.